Thermoforming Applications: What Jobs are Ideal Candidates?

Thermoforming provides an economical alternative to metal, fiberglass, or wood components and delivers key advantages like weight reduction, rapid prototyping, low tooling costs, and fast production turnaround time.

Because of the nature of the thermoforming process, combined with the availability of many material options, custom molded plastics offer numerous benefits to the end-user, including; durability, UV resistance, chemical resistance, flammability, toxicity, impact strength, high heat or cold temperature performance to name a few.

Because of the nature of the thermoforming process, combined with the availability of many material options, custom molded plastics offer numerous benefits to the end-user, including; durability, UV resistance, chemical resistance, flammability, toxicity, impact strength, high heat or cold temperature performance to name a few.

Raw materials are selected based on your requirements and specifications

But what are the specific types of jobs that are ideal candidates for thermoforming?

We suggest the following three scenarios, often in combination, are the ideal times to consider thermoforming:

- The final part is from six inches square up to 6' x 10'.

Why - Unlike injection molding, parts must be trimmed out of the excess material created in the molding process to produce a finished part. A part smaller than 6"x 6" is challenging to fixture for trimming operations. - The total weight of the parts in a traditional production release is at least 500 lbs and higher on specific material grades.

Why - To be as cost-effective as possible, the material is custom-ordered from extruders specifically for each production order. This ensures consistent material supply and traceability. Extruders require minimum production volumes to accept an order. - The time to production is short.

Why - Tooling lead times for thermoform tooling for both tooling built in-house and outsourced is generally much shorter than injection tooling due to lower complexity. A typical thermoform tool can be completed in 6-8 weeks from part design completion until produced first articles vs 3-6 months for injection.

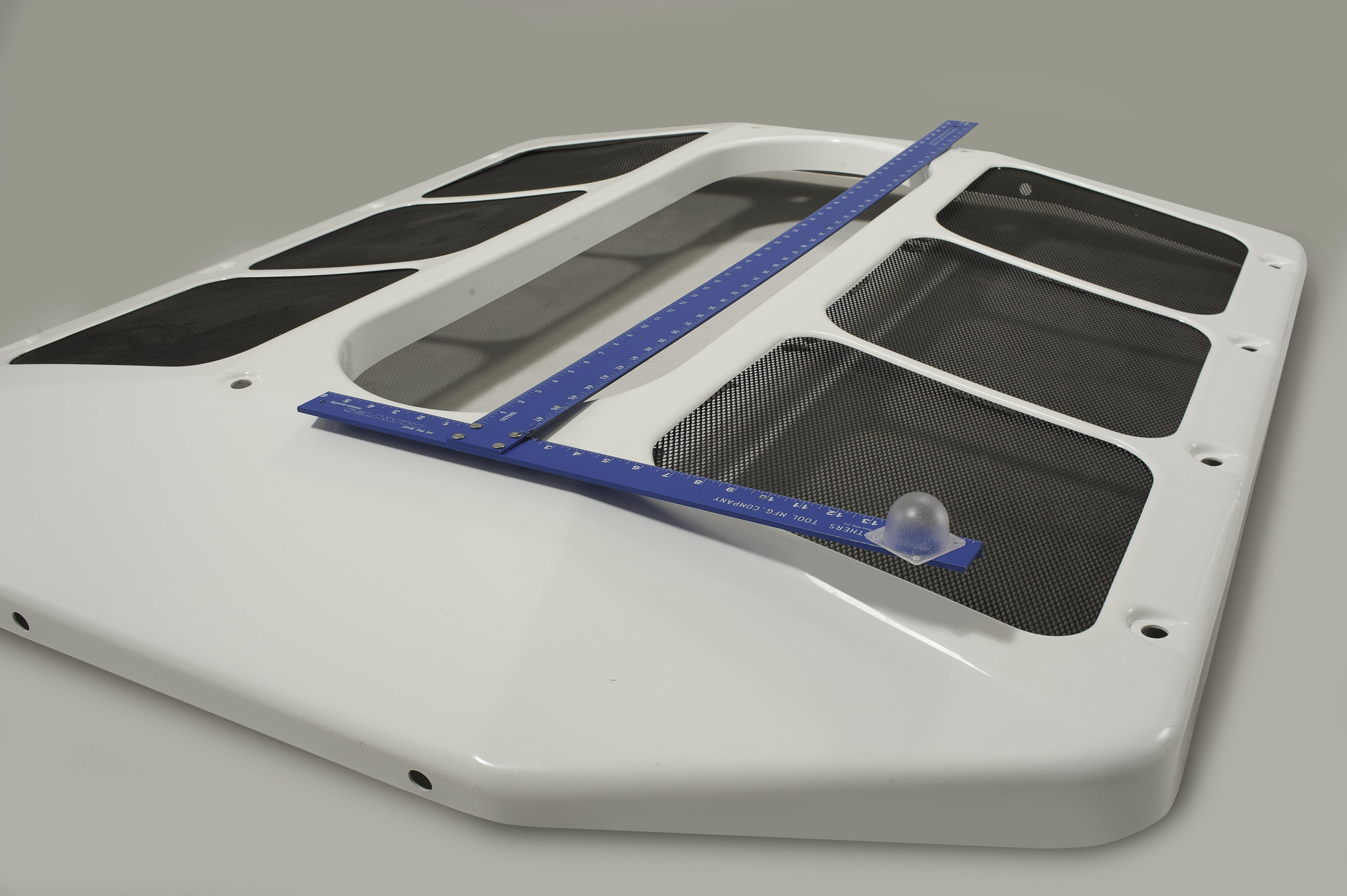

Custom Thermoformed parts

Quite simply, a thermoformed plastic part weighs less than an equivalent stamped metal part. This difference alone impacts all part handling operations, the ease of final part assembly, and the end product.

Thermoforming also improves the look and feel of a large part compared to a metal-stamped part. Plastics are molded into complex shapes in various colors and often deliver a more sleek and designed appearance than metal.

Custom molded parts often require a level of impact strength to meet safety and operational requirements. With an extensive range of resins available for thermoforming, plastic parts often exceed the impact strength of stamped metal parts. While the part may flex under impact, it will return to its original shape in instances where a metal part would have permanent deformation.

Thermoformed parts are easily built up as sub-assemblies and pre-assemblies, significantly reducing OEM production time and costs. Combining multiple elements into one, thermoforming reduces overall project cost, simplifies inventory management, and lowers installation time.

Components like bumpers, door panels, barriers, bins, exterior covers, housings, and trays are ideal candidates for conversion to thermoforming.

Low production volume thermoformed parts

An experienced thermoforming design team can turn around initial prototypes in a few weeks compared to months for injection molding and metal stamping suppliers.

An experienced thermoforming design team can turn around initial prototypes in a few weeks compared to months for injection molding and metal stamping suppliers.

Rapid tooling modifications and updates allow OEM manufacturers and assembly companies to get their new products to market faster and make ongoing updates and modifications without affecting just-in-time manufacturing requirements.

Because of thermoforming's underlying processes, tooling costs are low compared to other plastic molding processes and metal stamping. In most cases, only one-half of the mold is needed and not a male/female toolset, significantly reducing costs and design time and increasing design flexibility.

Typical thermoforming tools cost $10,000 - $50,000, compared to $150,000+ for other molding and stamping methods. If an OEM's production volumes are 10's, 100's, or even 1,000's per month, this tooling cost differential is a key factor in choosing thermoforming.

The economics of the thermoforming process from a manufacturing point of view also helps make low production volume runs economically feasible.

Thermoforming production lines are easier to set up and maintain than other injection molding technologies and metal stamping. There is also less downtime.

Thermoforming is a robust and reliable technology with a low cost to operate, meaning low-volume production jobs are an ideal fit.

Short time to production

We can machine wood or composite materials to create tooling for the fast turnaround of prototypes.

We can machine wood or composite materials to create tooling for the fast turnaround of prototypes.

We can make prototypes using various materials as well for testing and product review.

Thermoforming allows for simple but effective and accurate initial tooling to test designs and materials without spending tens of thousands of dollars on prototype tooling.

Wood tooling allows us to make approximately a dozen test parts—more than enough to do initial design feasibility tests.

Machinable composite tools are more robust and can be used to mold up to a few thousand parts. Parts can then be used for pre-production prototypes to verify and test fit, form, and function.

The critical factor in making thermoforming prototype tooling is that it can be built in a few weeks or even in a few days in some cases. Tools are easily modified without having to start from scratch.

Quick turnaround for prototype and production tools significantly reduces the time from initial design to production.

About Plastic Components, Inc.

We are a thermoform plastics molder specializing in medium and heavy gauge large vacuum-formed parts since 1972. We consolidate tooling, engineering, and manufacturing under one roof. We have forming capability up to 6' X 10' with fixture and CNC Trims.

We will deliver your thermoformed parts on time, to specification, and on your budget!